Press release:

Full control of lightweight parts production

Full control of lightweight parts production

Controlled parts handling at injection molding specialist RICO

Injection molding small silicone parts is one thing, but knowing how to handle them is something completely different. Manufacturer and mold producer RICO has produced billions of small parts and microparts over the years – and the company is fully aware of the need for special handling after the injection process.

“The basic process for the injection of small parts isn’t really any different from injection molding for large silicone components. The hard part begins with demolding and finishing,” explains Roland Angerer, Chief Technical Officer at RICO Elastomere Projecting GmbH, which is based in Thalheim in Upper Austria. RICO has been building molds, producing silicone and multi-component parts and developing its automation concepts for the past quarter of a century. The company is increasingly using active removal of parts.

Stable processes

RICO uses a valve gate nozzle system with molds containing up to 160 cavities. Mold development, the quality standards for components as well as process stability pose the main challenges when it comes to injection molding microparts. Angerer points to RICO’s philosophy: “RICO is synonymous with stable processes. Constantly changing settings and parameters is not part of our approach. We define our processes once and then identify the ideal configuration. After that, production of the injection molded parts needs to run without any further intervention.”

Full control over every single part

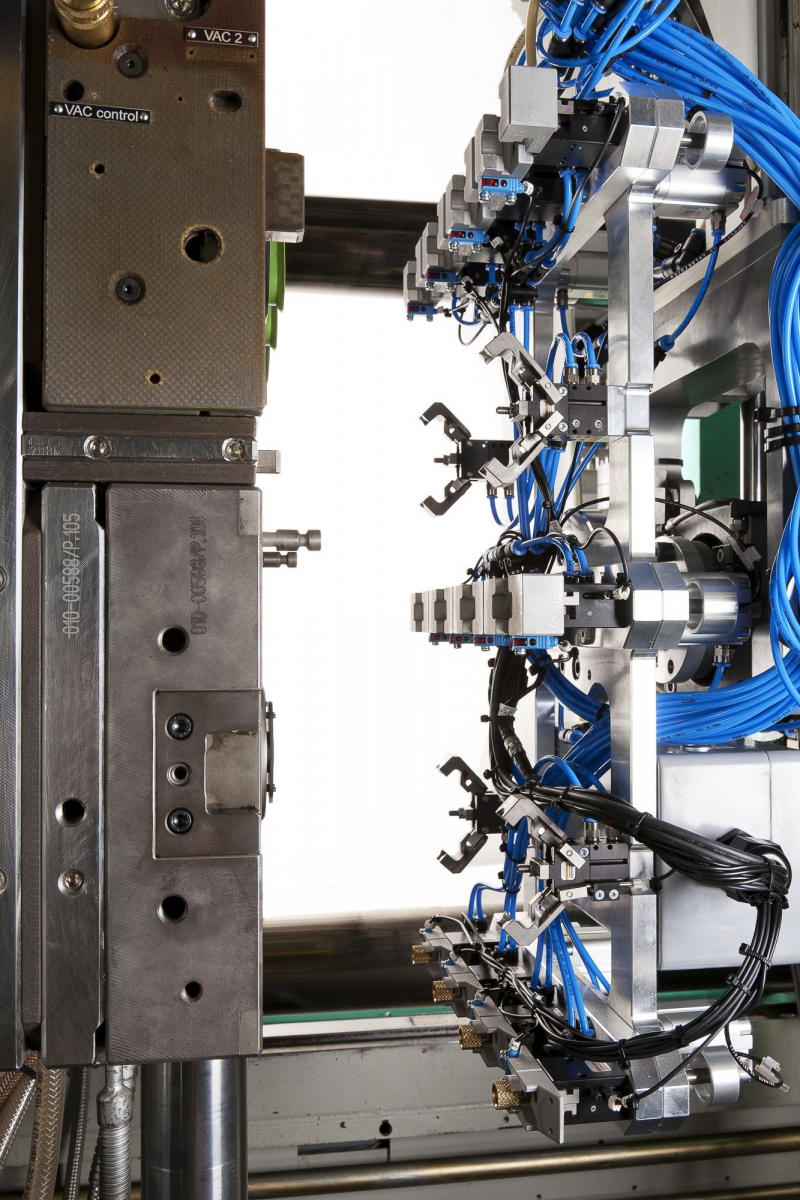

In some cases, parts are so fragile and light – and almost invisible to the naked eye – that manual handling after removal from the mold is not even an option. “If the handling machine lets go of a micropart, it’s not possible to put it back into position. That’s why we aim for full control all of the time,” says Angerer. After injection, parts are removed by a gripper and brought into position for finishing.

Downstream inline processes

Roland Angerer explains the reasons for the special handling of microparts: “Our target is to meet the highest quality levels in production.” So at RICO, downstream processes like slitting and flow-rate measurement are carried out inline directly after injection molding. Providing the right ambient conditions for production, coupled with the ability to carry out constant material checks in the in-house laboratory, serves to ensure that all microparts meet the requisite specifications. At the customer’s request, quality can also be verified and documented by means of camera inspections. This allows for production of parts for further processing in line with the zero-error principle.

And when it comes to processing, virtually anything is possible at RICO. The company no longer uses standard options such as tempering, talc-powdering and the like. Customer requirements are becoming more demanding, but RICO is facing up to this challenge in its usual style. As Angerer emphasizes: “We can offer options ranging from the automated shoring of parts through to packaging tailored to customers’ specifications and uses.”