New application at the Fakuma 2023

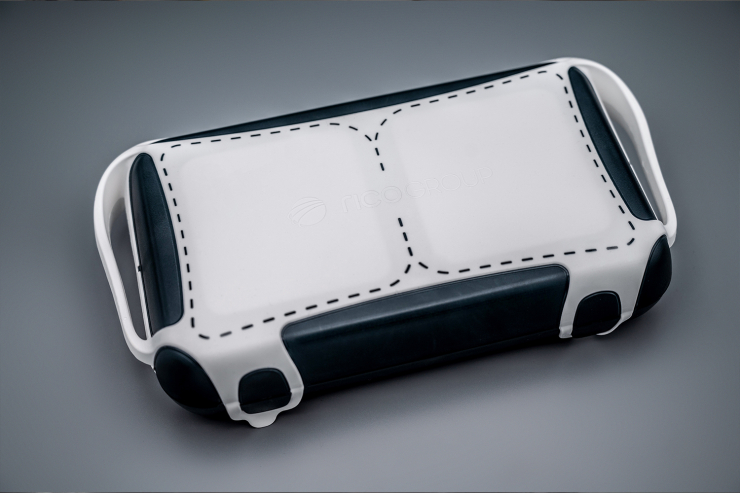

1-component-tools from RICO

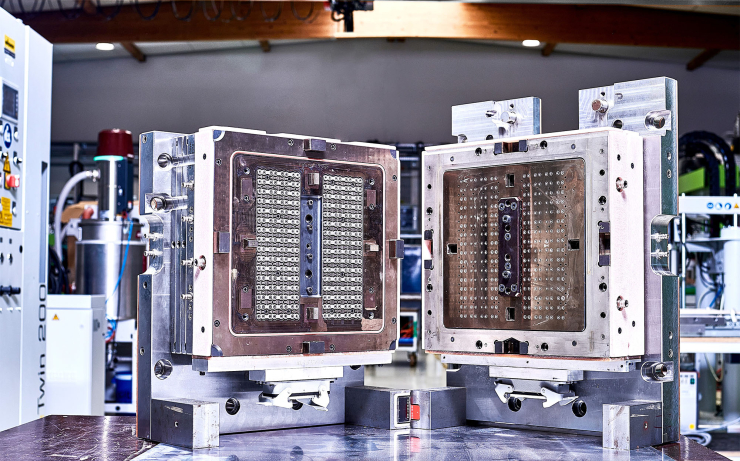

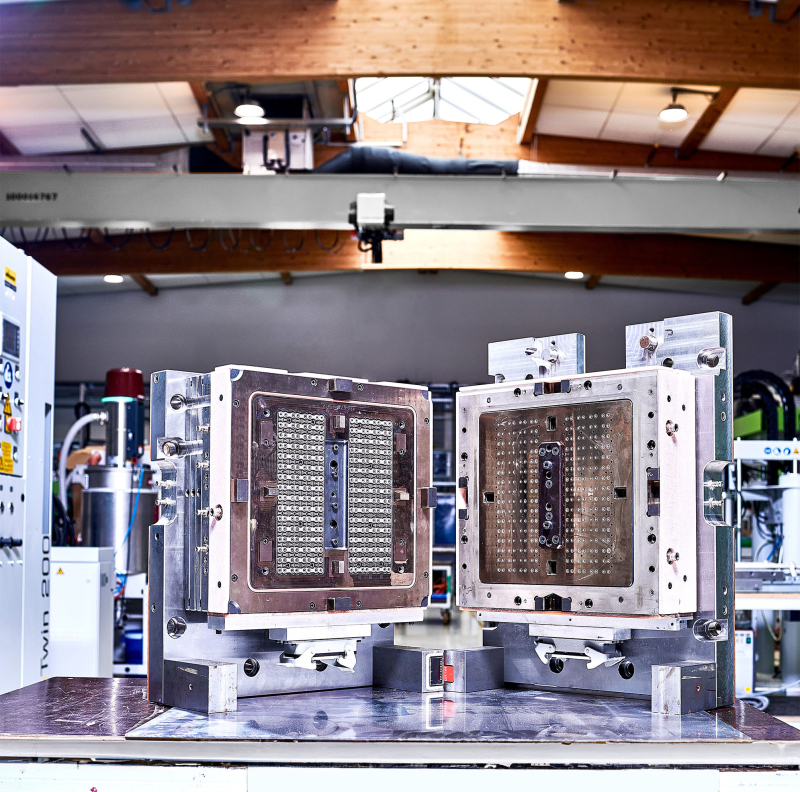

The 256-cavity mold with a shot weight of 0.6 grams each was designed for the series production of single-conductor seals made of liquid silicone injection molding. The cycle time is only 15 seconds with a clamping force of 130 tons.

Cold runner á la RICO

Despite the 256 cavities, the mold is extremely compact with a mold box size of just 446 mm x 611 mm x 351 mm. This, combined with an equally compact design of the entire injection molding time, results in increased productivity per square meter of surface area used. The cold runner with double nozzle system developed in-house by the RICO specialists ensures waste-free direct injection. Another advantage of the space-saving design and the 1:2 ratio of the cold runner nozzles: an optimum heat balance for the heating or cooling used and also the lowest possible offset. The tool definitely meets the highest standards of dimensional accuracy and part specification. The self-balancing cold runner ensures greater efficiency and time savings, as it does not have to be constantly and laboriously adjusted.

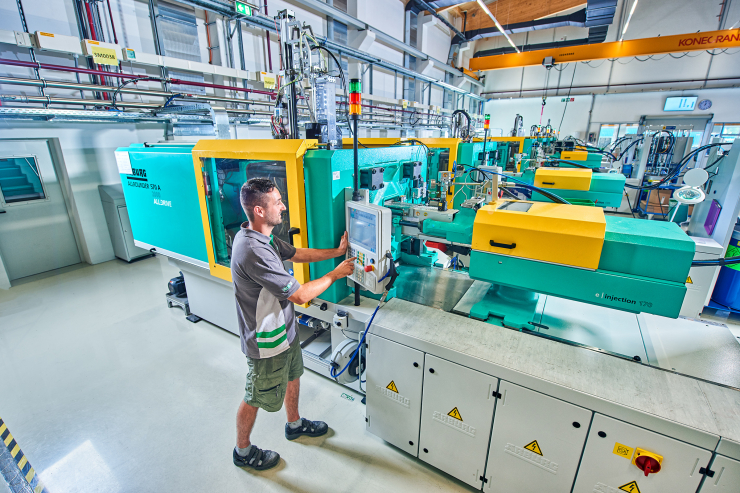

Ideal handling with high process reliability

The dual demolding system allows both production as bulk material and individual test separation. The individual nest separation leads to higher availability in production and thus takes a big step towards the well-known 0 ppm strategy. Thanks to the quick-clamping system and function integration - such as centring in the change package - it is very easy to change different sets of inserts quickly and without friction. An overarching technical feature of RICO molds: They run at clamping force even when cold without damaging components and avoid expensive downtimes and costs.

"Everything from a single source" - RICO avoids high levels of complexity and significantly increases process reliability thanks to the joint construction and design of the mold on the one hand and the automation on the other.